FARMACÉUTICA Y COSMÉTICA

ROVI Industria farmacéutica

Madrid. España

Realizamos los proyectos de laboratorio más seguros y eficientes del mundo en los que las personas investigadoras disfrutan logrando mejorar la sociedad.

En Burdinola realizamos estudios para desarrollos e instalaciones complejas de laboratorios, considerando de manera conjunta e integrada normativas, flujos de trabajo, procesos y equipamientos.

Saber más

Todo lo que necesitas para que tu laboratorio sea seguro y eficiente.

Mantén al día tu laboratorio en las mejores condiciones de seguridad.

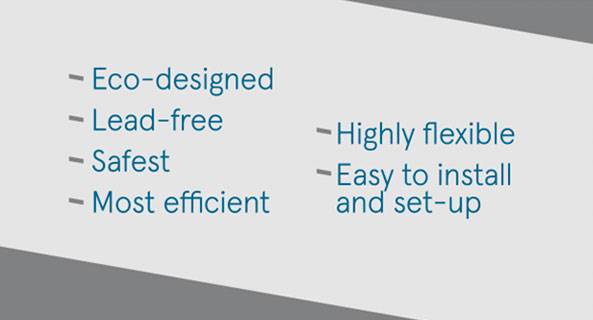

Nueva gama de vitrinas de gases. Lo último en seguridad y eficiencia.

Descubre la nueva gama eFlex

Nuestros más de 40 años de experiencia en el diseño de laboratorios, con más de 7.000 proyectos completados con éxito en 50 países, nos definen como una marca líder a nivel internacional.

FARMACÉUTICA Y COSMÉTICA

Madrid. España

INVESTIGACIÓN

Paterna. Valencia. España

FARMACÉUTICA Y COSMÉTICA

Parque Tecnológico. Derio. España

09/04/2024

12/02/2024

25/01/2024